Ferroalloy plants require precision, safety, and reliability to deliver consistent results, and our dedicated O&M division ensures that your plant achieves maximum productivity with minimum downtime.

01

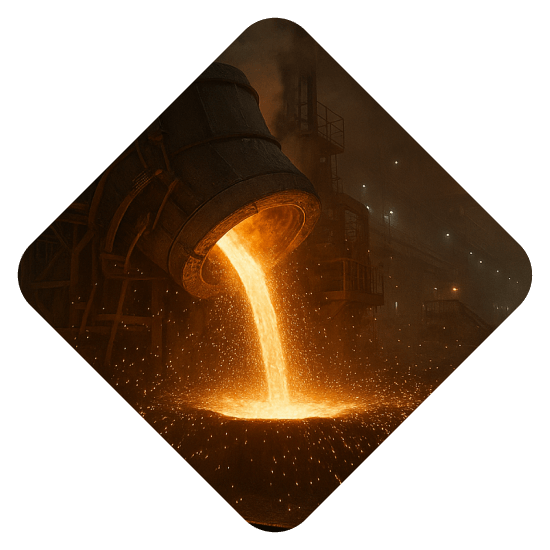

At AVR Energies, we bring the excellence of our O&M services into the world of Ferroalloy Plant Operations & Maintenance (O&M). Silicon Manganese, Ferro Manganese, Ferro Silicon, Ferrochrome and Calcium Carbide plants utilize electric arc furnaces to convert ores and other raw materials into metallic alloys and chemical compounds.

Industrial Furnaces particularly electric arc furnace operations (EAF), efficient raw material handling, metal processing, regular monitoring of electrodes and casting machinery. Furnace tapping of molten material and slag management is essential for operations

Inspection of Furnace Linings and Refractories, Cooling Systems checks, Electrical and Mechanical parts repair and replacement, Instrumentation Calibration (accuracy check), Safety Equipment Inspection, adjusting controls and fixing malfunctioning machinery fall under our preventive and corrective maintenance procedures

Schedule a Free Consultation Today!

Contact Us02

Whether you are an integrated steel producer or a stand-alone ferroalloy unit, AVR Energies is your trusted partner for sustainable, safe, and efficient O&M solutions

01 Silicon Manganese Plant

Feeding manganese ore and quartz in the correct ratio, maintaining the right electrode power. SiMn can act as a substitute for both FeMn and FeSi alloys

02 Ferro Manganese Plant

Heating electric arc furnaces to high temperatures for reducing the ore, FeMn is for its deoxidizing properties that significantly improve steel quality

03 Ferro Silicon Plant

Ensuring that the furnace lining and electrodes are in good condition, FeSi alloy is used in the production of other Silicon-based alloys

04 Calcium Carbide Plant

Proper blending of lime and coke, high temperatures (about 2000°C) are needed for the reaction

05 Ferrochrome Plant

Continuous supply of pre-heated chromite ore, coke, and fluxes to the furnaces using computerized batching systems and mechanized handling, FeCr is used for stainless steel production

06 Other Alloys

Alloys of nickel, tungsten and molybdenum are known for their high melting points and exceptional high-temperature strength and corrosion resistance.

03

With AVR Energies as your O&M partner, your ferroalloy plant operates with the highest standards of reliability, performance, and safety

01 Expertise in Furnace O&M and handling all major ferroalloy processes.

02 From raw material handling to final tapping and casting, we cover it all.

03 Proven track record of safe, disciplined operations.

01 Use of modern monitoring systems and diagnostics to ensure reliable plant performance.

02 Implementation of strict safety protocols, raw material and electrode inventory management, optimization of power consumption per ton of alloy produced.

03 Managing refractory life cycles, optimizing slag management, energy audit-backed process improvements and waste minimization strategies.

Get a Quote for Ferroalloy Plant O&M Services!

Contact Us© 2026. All Rights Reserved